This division works on the composition, microstructure, and properties of metallic materials and their surface protective coatings. Driven by industry demand, we have been engaged in long-term research on protective coatings for metallic material surfaces, as well as the behavior, mechanism, and application of material surfaces and interfaces. We have achieved a series of results in the preparation of high-strength and tough coatings, the study of substrate damage caused by coating cracking, and the research on reducing hydrogen embrittlement sensitivity of high-strength steel.

Research Areas

1. Surface damage and protection of materials

2. Design, preparation and properties of protective coating

3. Collaborative deformation mechanism of material interface

4. Surface and interface behavior, mechanism, and application of materials

5. Preparation of wear-resistant and corrosion-resistant coatings by laser cladding

6. Design and additive forming of light weight high strength superalloy

7. Environmental damage and cracking mechanism of metallic materials

8. Mechanical damage behavior and life prediction of components with defects

Research Highlights

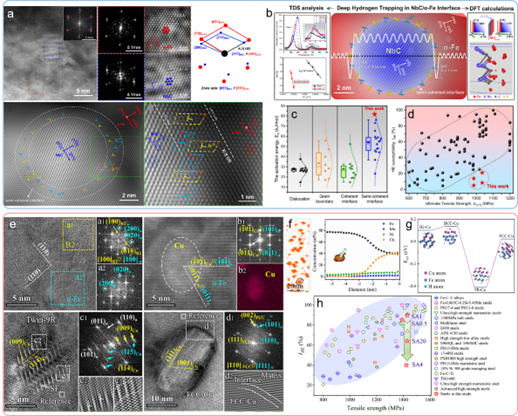

1. Significant achievements have been made in preparing high-strength and tough coatings, researching substrate damage induced by coating cracking, and developing hydrogen embrittlement-resistant metallic materials. The theory of coating-induced cleavage cracking in ductile metallic substrates has been proposed, and a protective method against substrate damage caused by coating cracking has been established. These advancements have significantly improved the fatigue resistance of coated metallic materials and resolved the technical challenge of brittle cracking in coated metallic structural components. (Acta Mater., 2020, 200, 686-698)

Fig.1. Atomic-scale investigation of deep hydrogen trapping in NbC/α-Fe semi-coherent interfaces.

2. A material design strategy combining machine learning and high-throughput experiments is proposed to rapidly screen ultrahard high-entropy ceramic coatings. The composition and process parameters of the coating are used to predict the hardness. The coating hardness predicted by this method is 9% higher than in the quinary system from the original training dataset. These coatings were successfully synthesized through high-throughput experiments. Machine learning combined with high-throughput experimental methods can effectively accelerate the composition design of multi-component materials. (Ceram. Inter., 2022, 48, 32064-32072)

Fig.2. Design of super-hard high-entropy ceramics coatings via machine learning.

3. Surfacing welding Co-based alloys coatings is often used to improve the wear and corrosion resistance of valve sealing surface. To tackle this issue, high-speed laser cladding technique has been employed to obtain 3533-00 Fe-based cemented carbide coatings on power valve sealing surface. And 3533-00 Fe-based cemented carbide coating demonstrates better wear and corrosion resistance than the Stellite 6 Co-based alloy coating. These findings may provide a method for designing wear and corrosion resistant coatings for valve sealing surface. (J C Fu, W Y Gui, J Y Qin, et al. Surf Coat Tech. 2024, 480, 30: 130594; Y H Ding, W Y Gui, B X Nie, et al. JMRT, 2023, 24: 4118-4129; W Y Gui, C Zhong, J Y Gu, et al. npj Mat Degrad, 2022 6, 37.)

Fig.3. Corrosion-resistant characteristics and photos of valve sealing surface coated by 3533-00 Fe-based cemented carbide coatings.

4. Here, an electron beam selective melting (EBM) technique was employed to shape Ti-48Al-2Cr-2Nb alloy to combat its intrinsic brittleness and insufficient hot workability. The maximum room temperature tensile strength of as-deposited Ti-48Al-2Nb-2Cr alloy reaches 854.6 MPa with an elongation of over 2%. And the maximum high-temperature tensile strength of EBM-formed Ti-48Al-2Nb-2Cr alloy reaches 707 MPa at 650 ℃ with an elongation over 3.5%. According to these results, the mechanical properties of our EBM Ti-48Al-2Cr-2Nb alloy are superior to those previously reported. (J W Feng, W Y Gui, Q Liu, et al. JMRT, 2023, 26: 9357-9369.)

Fig.4. Comparison results of physical photos and mechanical properties of blades.

5. In order to evaluate the service behavior of nuclear power materials, the stress corrosion cracking, corrosion fatigue damage mechanism and prediction model of typical power components were studied. In particular, the environmental damage mechanism and properties of materials and structural components containing defects (scratches, dents and notches) were systematically studied, which provides technical support and guarantee for the safety of nuclear power materials in service. (Z.H. Li, Corros. Sci., 2025, 245, 112702; Z.H. Li, Corros. Sci., 2024, 227, 111741; Z.H. Li, Corros. Sci.,2023, 212,110953.)

Fig.5. Corrosion fatigue damage mechanism and life evaluation of Inconel Alloy 690TT steam generator tube in high temperature pressurized water.

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026